- Monday 8:00AM - 5:30PM

- Tuesday 8:00AM - 5:30PM

- Wednesday 8:00AM - 5:30PM

- Thursday 8:00AM - 5:30PM

- Friday 8:00AM - 5:30PM

- Saturday 8:00AM - 12:00PM

- Sunday Closed

2025 McHale Fusion Vario Plus - Variable Chamber Integrated Baler Wrapper

Fusion Vario Plus - Variable Chamber Integrated Baler WrapperTHE MOST ADVANCED INTEGRATED BALER WRAPPER RANGE The McHale Fusion range has been developed with a focus on operator comfort and machine performance, while still ensuring the renowned simplicity and reliability is maintained. Our specialist team of engineers have maximised machine intake and output, increased bale density and reduced maintenance intervals to ensure the Fusion range of machines surpasses all your baling and wrapping expectations. These levels of comfort, when paired with proven features such as the patented bale transfer system and the vertical wrapping ring, enable the McHale Fusion range of machines to offer durability, reliability and high output to the end user. |

|

The MCHALE FUSION VARIO PLUS is a fully automatic integrated baler wrapper which can apply film or net wrap to the barrel of the bale, delivering optimum bale shape and bale density. The Vario Plus can provide high quality fodder through the use of the film binding system, resulting in better quality silage and easier feed out. This machine provides a number of benefits as the task of baling and wrapping can be carried out using one machine. There is also a labor saving, as one operator, one tractor and one machine can complete baling and wrapping duties. The McHale Fusion Vario Plus also has the ability to make bales of hay and straw from 0.6m to 1.68m (2’–5’6″) but in haylage or silage, it produces bales from 1m to 1.45m (3 ‘ 3 “–4 ‘8 “) to allow for wrapping. It features two unique patents; a patented bale transfer system and a patented vertical wrapping ring. The machine is ISOBUS compatible and can be operated through the tractor terminal or ISO-Play 7 or 12 terminals. |

Film BindingThe concept of putting film on the barrel of the bale is known as “Film Binding Technology.” The plastic, which is applied to the barrel of the bale forms an additional layer of wrap across the largest surface of the bale, whilst also binding the bale together. The film which is applied to the barrel of the bale can be stretched according to the manufacturers recommendations which is a higher ratio than can be achieved with net wrap. This additional layer of film on the barrel of the bale provides higher quality silage as the film can be stretched more than net. This in turn, expels more air, resulting in better silage quality. By using film to bind the bale together, removal and recycling of the film is made easier as the farmer is only left with one form of waste to recycle and can avoid the unpleasant and time consuming job of separating net from the plastic. |

Patented Bale TransferWhen the bale is bound in the bale chamber, the bale chamber splits horizontally. As the top section of the bale chamber moves up, the lower section of the bale chamber simultaneously moves up and out, transferring the bale onto the wrapping platform. |

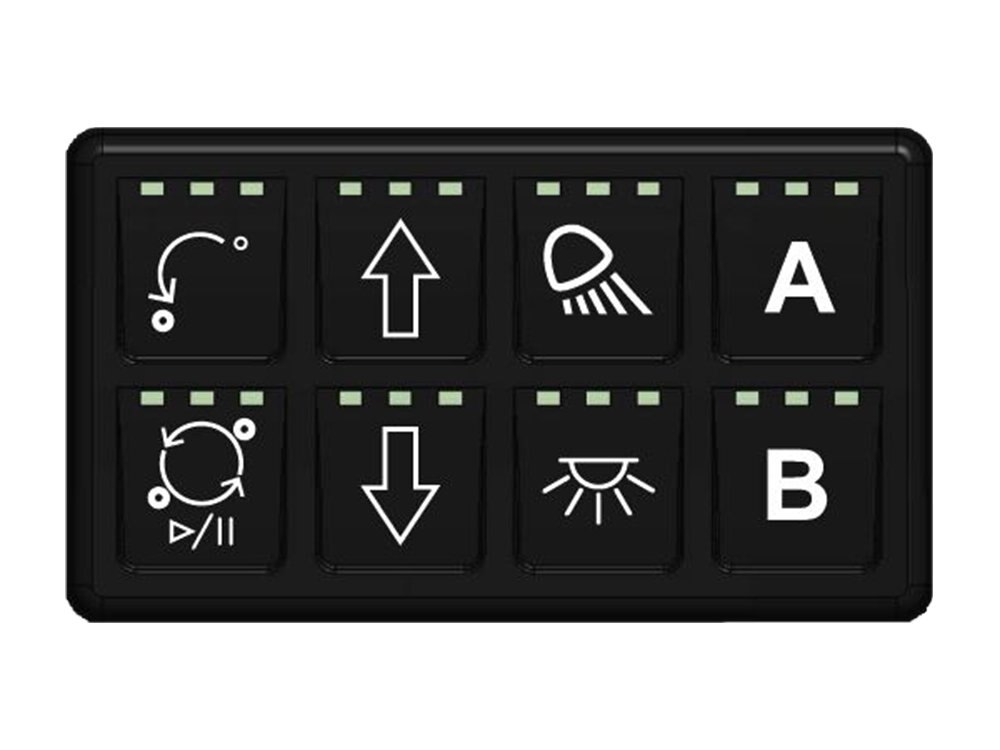

Control TerminalsThe McHale Fusion Vario Plus is fitted with ISOBUS as standard. For customers without an ISOBUS tractor, an optional ISO-PLAY 7 or ISO-PLAY 12 terminal can be used. Through the ISOBUS tractor’s terminal or McHale’s ISO-PLAY terminals, the operator is provided with clear indicators of machine performance and allows for increased levels of monitoring, through the graphic display. |

Fusion Vario Plus - Variable Chamber Integrated Baler WrapperThe McHale Fusion Vario Plus is a fully automatic variable chamber integrated baler wrapper, which consists of a high output baler and a vertical wrapping ring. The machine benefits from two unique patents; a patented bale transfer system and a patented vertical wrapping ring. |

Spotlight Series | McHale Fusion Vario PlusIn this episode of our Spotlight Series, we take a look at the new McHale Fusion Vario Plus which is now ISOBUS controlled and binds with either film or net. |

| 2.1m Profi-Flo Pick-Up | Film or Net Binding | ISOBUS/ ISO-Play |

| 2x Inbuilt Camera System | Drop Floor Unblocking System | Double Drive Variable Bale Chamber |

| 15 Knife Chopper Unit with Heavy-Duty Rotor | Single Belt Bale Chamber with Endless Belt | Bale Shape Assist Indicators |

| Patented Bale Transfer Delivering Higher Output | High Speed Vertical Wrapping Ring | Spring Tine Crop Roller |

| Diameter | 0.6 – 1.68m (2’–5’6″) |

| Width | 1.23 m (4′) |

| Bale Chamber Feed | 15 Knife Chopper Feed Rotor |

| Number of Belts | 1 |

| Type | NRF or Net |

| Layer Adjustment | In-Cab |

| Net or NRF Roll Capacity | 4 |

| Binding System | Infinite Stretch |

| Control | Manual or Automatic |

| Gearbox | Split Drive |

| Pick Up Protection | Slip Clutch |

| Main Drive Protection | Cam Clutch |

| Chain Lubrication | Continuous |

| Bale Chamber | Double Drive |

| Control System | ISOBUS |

| Operation | Fully Automatic |

| Density Adjustment | In-Cab |

| Bale Size Adjustment | In Cab |

| Inbuilt Camera | 2x Inbuilt Camera |

| Axle | 8 stud |

| Brakes | Standard: Hydraulic (Option: Air) |

| Tyres Standard | 650/50/22.5 |

| Tyres Optional | 680/50/22.5 |

| Bale Kicker | N/A |

| Side Tip | Option |

| Road Lights | Standard |

| Minimum Hydraulic Flow | 45 l/min @ 180 bar |

| Hydraulic System | Open Centre, Closed Centre or Load Sensing |

| Electronics | 12 Volt DC, 20 amp |

| Minimum Power Requirements | 85kW (114hp) |

| Length | 6.3m (20’8″) |

| Width | 2.94m (9’8″) |

| Height | 3.3m (10’10”) |

| Weight | 6500kg* (14,330 lbs) |

| Name | Link |

| Download Product PDF | Download |